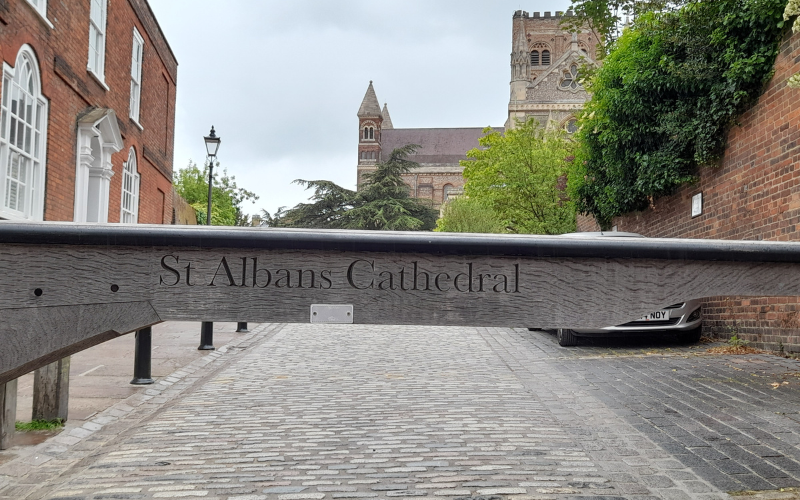

St Albans Cathedral benefits from an UltraScape installation

St Albans Cathedral, with a history dating back to 1066, faced challenges with its cobbled drive, which posed safety concerns due to lifting and movement under vehicular traffic. The client sought a solution that would maintain historical aesthetics while ensuring durability. Accredited Contractor, Ground Control and Accredited Supplier, Instarmac, addressed this by employing the BS 7533-compliant mortar paving system. The process included the application of eco-bed bedding mortar for a solid foundation, pro-prime slurry primer for a secure bond, and flowpoint flowable grout for jointing.

Background

Dating back as far as 1066, St Albans Cathedral is still as majestic today as it was centuries ago. Several groups have a role in the governance and management of this beautiful cathedral, all of which are passionate about its conservation.

In addition to updating the soft landscaping at the front of the beautiful Cathedral, Ground Control was also asked to replace the cobbled drive – a heavily trafficked area that connects the main road to the Cathedral.

The Challenge

The client was disappointed that the existing cobbles were lifting and moving under regular vehicular traffic. With lots of people visiting St Albans Cathedral every day, there was additional concerns that the loose cobbles could become a dangerous trip hazard.

Despite these issues, it was important to St Albans Cathedral that the newly laid cobbled driveway was kept in keeping with their history. The cobbles needed to look like they had been there for many years and installed with materials that would not lift or de-bond again in the future.

The Solution

Following thorough and detailed conversations between the client, Ground Control and UltraScape, it soon became clear that using BS 7533-compliant paving installation materials was the only way forward.

Comprising of eco-bed bedding mortar, pro-prime slurry primer and flowpoint flowable grout, Ground Control utilised UltraScape’s BS 7533 compliant mortar paving system to relay the cobbles to create an exquisite, seamless finish.

To begin, UltraScape eco-bed was applied to the area to produce the ultimate foundation for the paving. UltraScape eco-bed can be laid from 10mm to 100mm, is shrinkage compensated and can be opened to foot traffic after just 12 hours, allowing contractors to move on to the next part of the installation quickly. In addition to its superb performance qualities, eco-bed also contains 20% recycled material.

With eco-bed in place, Ground Control coated the mortar and paving with pro-prime slurry primer to create an exceptional bond. Using a primer eliminates costly failures caused by general wear and tear and gives you confidence and peace of mind that the paving slabs will not come loose.

To complete the installation, market-leading flowpoint flowable grout, in Charcoal, was used to joint the cobbles. With an initial set of just 15 minutes, and a walk on time of one hour, it is unsurprising that flowpoint has become synonymous with fast application, cost-effective and robust jointing.

Results

The client was delighted with the finished result, so much so that they are now reviewing the area surrounding St Albans Cathedral and are looking to relay, or replace, the paving using UltraScape’s mortar paving installation system.

What’s more, Ground Control were so pleased with UltraScape’s products and services that they are now utilising their BS 7533 compliant materials on projects in Bognor Regis and the Imperial College in London.